Products

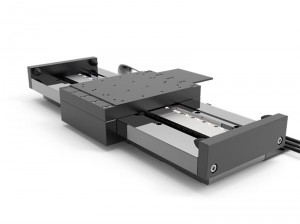

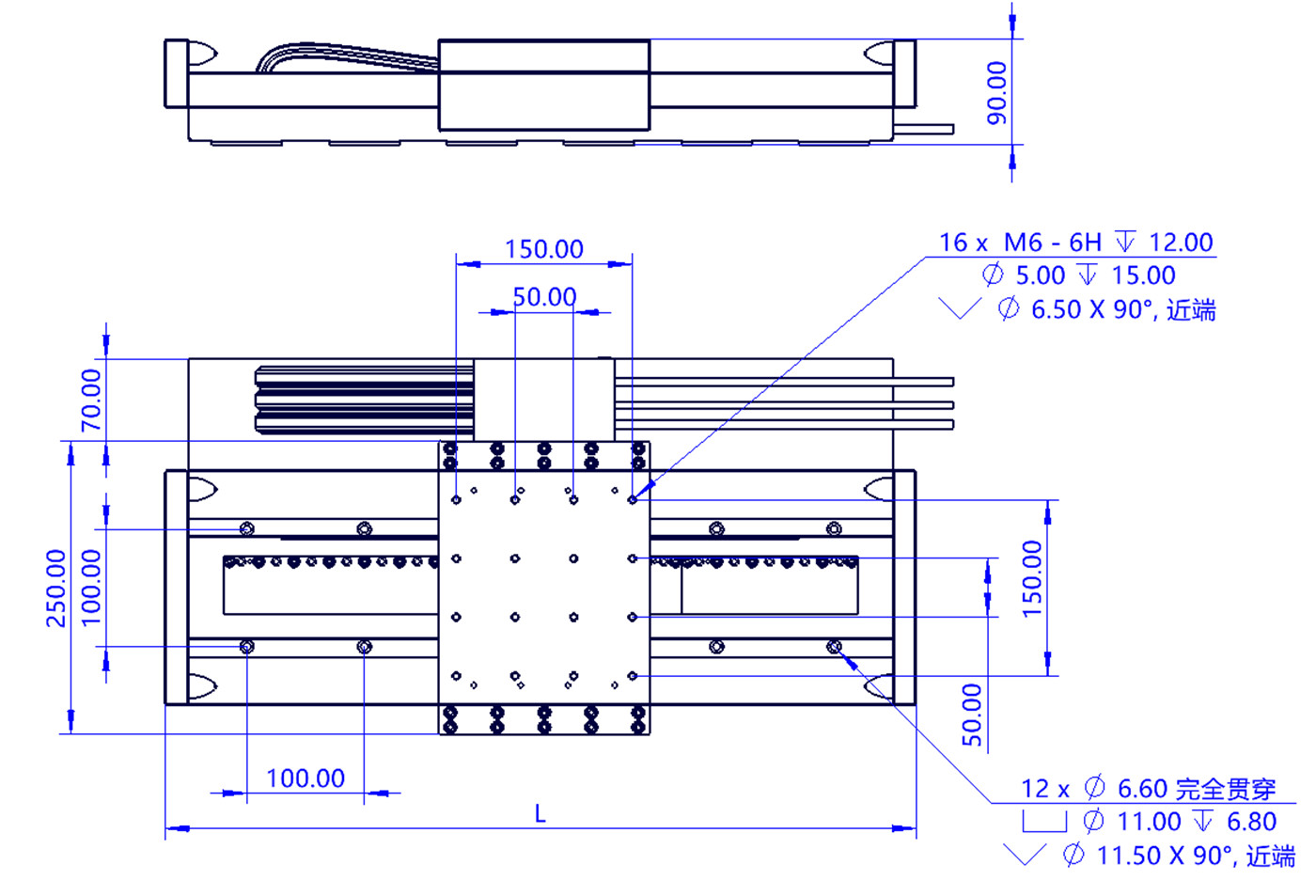

E-ABL250-X One-dimensional Ultra-precision air bearing platform

Linear Motor Drive

The driving force behind this stage is Precision-stage brushless linear servomotor. The utilizes an ironless forcer, which means there is zero cogging and no attractive forces – resulting in unrivaled smoothness of motion. Since the stage is friction-free and the motor has zero cogging, extremely fine resolutions are achievable.

Zero Maintenance

The noncontact air bearing, noncontact linear motor drive and noncontact feedback device ensure years of maintenance-free operation at the high performance levels that are expected of equipment. Because there is no mechanical contact between moving elements, the E-EC-ABL-X experiences no wear or reduction in performance over time. Service life is virtually unlimited, and since there is no lubrication – only clean, dry gas – air bearings are ideal for clean room and medical applications.

Application Fields

positioning systems are ideally suited for many high-precision applications such as metrology, photonics, and precision scanning in semiconductor or flat panel display manufacturing.

Thanks to the friction-free motion, no particles are formed, which makes stages ideal for cleanroom applications.

Encoder

● filter and air preparation kits

● Single and multi-axis motion controller

● XY setups and individual configurations

● Base plates made of granite and systems for reducing vibration

| Specification | ABL250-100 | -200 | -300 | -400 | -500 | -600 |

| Effective travel [mm] | 100 | 200 | 300 | 400 | 500 | 600 |

| Opticval Encode resolution [nm] | 5nm Opticval Encode resolution | |||||

| Repeatability Accuracy [nm] | ±50 | ±50 | ±100 | ±150 | ±200 | ±250 |

| Accuracy | 2um/100mm (After calibration can be less than0.3um/100mm) | |||||

| Straightness [um] | ±0.4 | ±0.5 | ±0.6 | ±0.75 | ±1 | ±1.5 |

| Flatness [um] | ±0.4 | ±0.6 | ±1 | ±1.5 | ||

| Max Speed | 2m /s | |||||

| Max acceleration(no load) | 2G | |||||

| Load Capacity-Horizontal [kg] | 35kg | |||||

| Load Capacity-Side [kg] | 20kg | |||||

1) What is the MOQ?

A: MOQ is 1 pcs.

Sample is available for customer to check the quality before bulk order.

2) Do you accept OEM?

A: Yes, OEM and ODM is warmly welcomed.

It is our company’s strength, we can customize the LCD monitor so that can fully meet customers’ requirements.

3) What payment methods does your company accept?

A: T/T, Western Union, Paypal and L/C.

4) Are the products customizable?

A: We provide the ultimate engineered motion solutions for our clients. In many cases this involves customizing or configuring our standard products to a client’s unique application and specifications. Please contact us if you’re interested in customizing or configuring one of our standard products, or if you’d like to work with our engineering team to design a unique solution to meet your needs of the feedback source. If this velocity is exceeded, the commutation initialization is no longer valid, and commutation must be reinitizlized.

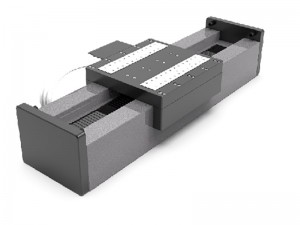

5)What is gantry stages?

A: The gantry stages are designed to provide unsurpassed repeatability and excellent throughput under real world operating conditions. Our gantry stages are designed to move such items as inspection cameras, laser heads, or specific customer tooling over either removable substrates or fixtures mounted to the base of the system. The gantry base can be provided with mounting holes for interfacing a customer’s hardware to the stage. Due to its simplicity and ease of assembly, it is the ideal gantry stage configuration for OEMS and system integrators building machines for demanding applications. Many of Dover Motion’s standard screw driven and servo motor linear products can be integrated together as a gantry stage to achieve an application’s required accuracy and travel for XYZ motion.

●Pre-formatted base for ease of integration;

●Risers to provide space between the base and moving beam;

●Integrated cable tracks and hi flex cable;

●All axes tested together and burned in to ensure performance and reliability requirements are met before shipment.